Industrial design often calls for materials that are not only strong and durable but also adaptable. From creating tight seals in machinery to forming protective covers for sensitive equipment, flexible plastic profiles are a reliable choice across various sectors. Among these, flexible PVC extrusion stands out for its ability to meet complex and changing demands.

Manufacturers that rely on custom solutions now prefer flexible PVC extrusion in India for both small and large-scale industrial applications. This process is efficient, affordable, and ideal for producing high-quality components designed to fit precise requirements.

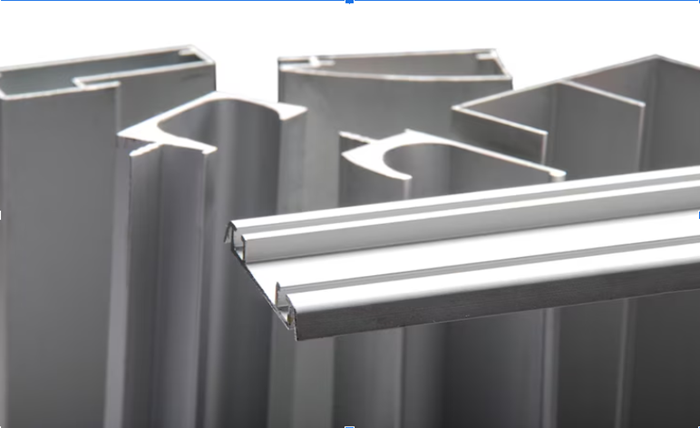

What Is Flexible PVC Extrusion?

Flexible PVC extrusion involves shaping polyvinyl chloride (PVC) using heat and pressure. The material is passed through a die or mould to produce a continuous profile with a specific shape and size. The inclusion of plasticisers in the PVC compound allows the finished profile to bend and stretch without cracking or losing form.

This technique is used to make products such as sealing strips, edge trims, protective sleeves, tubes, weather strips, and more. Its ability to deliver consistency across long production runs makes it suitable for industries that demand bulk manufacturing without compromising on accuracy or quality.

Flexible PVC extrusion is not only versatile but also essential for various industries, offering solutions that are both durable and adaptable. This adaptability is crucial in sectors like automotive, construction, and even HVAC systems, where custom solutions are often required. For instance, in the HVAC industry, the need for reliable and efficient components is paramount. Companies specializing in services such as ac repair montgomery rely on high-quality materials to ensure optimal performance and longevity of their systems. By utilizing flexible PVC, these companies can provide tailored solutions that meet specific client needs, ensuring both efficiency and customer satisfaction.

Where Flexible PVC Extrusion Is Used

Flexible PVC profiles are found in a wide range of sectors. Below are some examples that show just how versatile this process is:

Construction and Building Materials

Flexible PVC is commonly used in door seals, window gaskets, edge trims, and insulation profiles. These components help improve energy efficiency by preventing air or water leaks, especially in high-rise buildings, industrial sheds, and commercial properties.

Automotive and Transport

The automotive industry uses flexible PVC for interior trims, seals, tubing, and noise-dampening profiles. It offers resistance to oils, fuels, and temperature shifts, making it ideal for vehicles that operate in different environments.

Electrical and Electronics

Cables, wiring conduits, and tubing made from flexible PVC are used to shield electrical systems. These profiles provide insulation and reduce the risk of damage from moisture or mechanical stress.

HVAC Systems

Flexible PVC is used to manufacture seals, dampers, and insulation profiles in heating, ventilation, and air conditioning systems. These parts must be able to flex and maintain shape while preventing leaks and noise.

Furniture and Fixtures

PVC trims, bumper guards, and corner protectors are used in office furniture, retail displays, and industrial workstations. The soft, smooth finish makes them ideal for user safety and protection against wear and tear.

Advantages of Flexible PVC in Industrial Use

Flexible PVC profiles are known for their performance and reliability. Some of the key benefits include:

- Adaptability: Suitable for applications that require bending or fitting into irregular shapes.

- Durability: Resists chemicals, water, UV light, and temperature variations.

- Ease of Installation: Lightweight profiles that are easy to handle, cut, and fit.

- Consistency: Allows uniform quality and dimensions across large production volumes.

- Cost Efficiency: Competitive pricing without compromising quality or customisation.

Key Design Considerations

When choosing or designing a flexible PVC profile, it is important to consider:

- Wall Thickness: Affects flexibility and durability.

- Shore Hardness: Indicates the softness or stiffness of the material.

- Application Temperature: The profile must perform well under the working conditions.

- Material Grade: Food-safe, UV-stable, or flame-retardant compounds may be needed for specific industries.

- Joining Methods: Profiles may need to be welded, glued, or clipped in place depending on usage.

Flexible PVC and Sustainability

Flexible PVC can also contribute to sustainability in manufacturing. With advancements in formulation, many profiles are now made from recyclable or low-impact materials. Profiles can be reprocessed and reused, helping reduce overall waste. In some cases, manufacturers use post-industrial recycled PVC, offering a cost-effective and eco-conscious option without losing product integrity.

Bulk Production with Flexible PVC Extrusion

When industrial projects need high quantities of consistent components, flexible PVC extrusion is one of the most efficient methods available. Whether it’s for standard designs or custom profiles based on CAD drawings or samples, this process ensures high repeatability and low material wastage.

Many businesses in India are turning to extrusion companies that offer made-to-order services for industries like construction, automotive, electricals, and infrastructure. These services save time and reduce the risk of stock shortages during large installations or ongoing maintenance work.

Why M3 Extrusion Is a Reliable Manufacturing Partner

M3 Extrusion supports industries with high-volume, custom production of flexible PVC profiles. We work with clients across construction, electrical, and machinery segments to supply made-to-order parts that meet exact requirements. Our process includes:

- In-house tooling and die development

- Short lead times for bulk orders

- Strict quality control

- Custom colour and material options

- On-time delivery with consistent dimensions

By working closely with clients, we help reduce the chances of design errors, delays, or compatibility issues, especially in time-sensitive or large-scale installations.

Frequently Asked Questions

Q1: Is flexible PVC safe to use in outdoor environments?

Yes, with the correct additives, flexible PVC profiles can withstand UV rays, moisture, and extreme temperatures.

Q2: What’s the typical lifespan of a flexible PVC profile?

When used in the right application, these profiles can last for several years without hardening, cracking, or losing shape.

Q3: Can you customise profiles based on our design or sample?

Yes. At M3 Extrusion, we manufacture profiles based on customer-provided drawings or physical samples.

Q4: Are flexible PVC profiles available in multiple colours?

Yes. We offer a range of colours based on usage and design needs, including colour-matching services.

Q5: Is flexible PVC recyclable?

In many cases, yes. We also offer recycled material options for clients interested in reducing environmental impact.