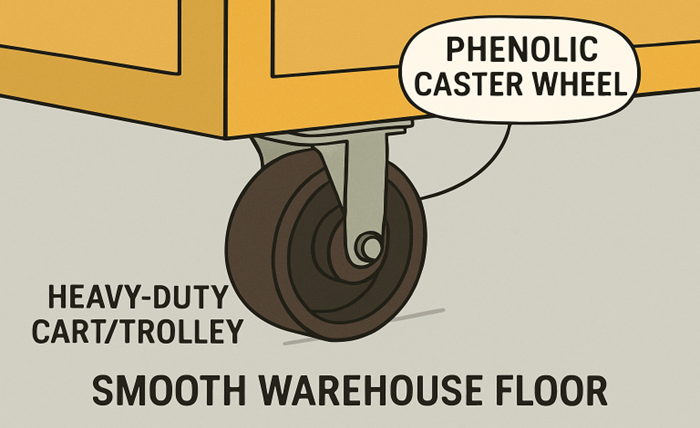

Introduction to Phenolic Caster Wheels

In industrial environments, reliable mobility is crucial for both efficiency and safety. This is where phenolic caster wheels come into focus. Engineered from tough phenolic resin reinforced with robust fibers, these wheels are designed to support heavy machinery and equipment with ease. Their unique composition delivers the durability and strength required for demanding applications, enabling hassle-free movement and positioning in even the busiest workspaces. Whether you’re outfitting warehouse carts or factory trolleys, phenolic casters stand out for their balance of ruggedness and practicality.

One of the chief reasons industries gravitate toward phenolic wheels is their impressive strength-to-cost ratio. They deliver the robustness expected from premium wheel materials but at a far more accessible price point, making them a preferred choice for businesses aiming to maximize equipment performance and lifespan without overspending.

Key Advantages of Phenolic Caster Wheels

- High Load Capacity: With the ability to support substantial weights without warping, phenolic wheels are a practical solution for moving heavy machinery and dense loads.

- Cost-Effectiveness: Phenolic wheels are less expensive than all-metal alternatives, providing industrial-grade performance while keeping costs in check.

- Floor Protection: Their hard, non-marking surface minimizes the risk of unsightly streaks or marks on well-maintained flooring, particularly on polished concrete.

- Chemical Resistance: These wheels withstand exposure to oils, greases, and a range of industrial solvents, making them suitable for use in manufacturing and automotive settings.

- Temperature Tolerance: Adaptable to a broad temperature range—from cold to extreme heat—phenolic casters maintain their structural integrity under various operating conditions.

In addition to their load-bearing capabilities, phenolic caster wheels can reduce the effort required to move heavy loads by reducing rolling resistance on smooth, level surfaces. This advantage improves the productivity and ergonomics of material handling operations.

For businesses looking to optimize their warehouse or production lines, phenolic casters provide a long-lasting, economical solution without compromising safety or efficiency. Organizations seeking to improve handling without damaging underlying surfaces are increasingly opting for this proven wheel technology.

Limitations to Consider

- Noise Levels: The hard surface of phenolic wheels tends to generate more noise, especially when rolling across concrete or unfinished floors.

- Moisture Sensitivity: Prolonged exposure to water or high humidity can compromise the resin, potentially leading to swelling or delamination over time.

- Floor Wear: While non-marking, the hardness of phenolic wheels can accelerate floor wear compared with softer wheel materials such as rubber or polyurethane.

- Brittle Under Impact: Phenolic casters, though tough, are more susceptible to chipping or cracking if they’re subjected to sharp impacts or dropped onto hard surfaces.

Ideal Applications for Phenolic Caster Wheels

Phenolic caster wheels are particularly favored in settings that require excellent abrasion resistance, consistent performance under sustained heavy loads, and cost-efficiency. According to PurposeOf, these wheels are ideal for enhancing everyday mobility and offer practical solutions for a variety of applications in both industrial and commercial environments. Their usage spans across:

- Warehouses and logistics centers for carts and rolling racks

- Manufacturing floors for conveyor stands and assembly tables

- Distribution centers for heavy pallet jacks

- Automotive facilities requiring resistance to chemicals and oils

- Institutional environments with high equipment turnover

Phenolic casters are ideal for use over smooth concrete, where the risk of floor damage is minimal and ease of movement is paramount. However, they are best avoided in damp or outdoor conditions due to moisture sensitivity.

Maintenance Tips for Longevity

Proper maintenance extends the functional lifespan of phenolic caster wheels. Regularly inspecting the wheels for cracks, chips, or delamination is crucial, particularly after exposure to rough handling or chemicals. It’s also essential to avoid prolonged exposure to moisture, as this can degrade the core material. Keeping the wheels clean from debris, dust, and industrial residues reduces friction, lowers rolling resistance, and minimizes noise over time.

Conclusion

Phenolic caster wheels remain a standout solution for industrial users who require a blend of durability, capacity, and affordability. Their distinct advantages outshine many alternatives, particularly in dry, high-load environments where efficiency and minimal maintenance are top priorities. While not the right choice for every situation, especially when facing moisture or uneven terrain, these wheels continue to play an essential role on factory floors, in warehouses, and anywhere reliable heavy-duty mobility is needed.